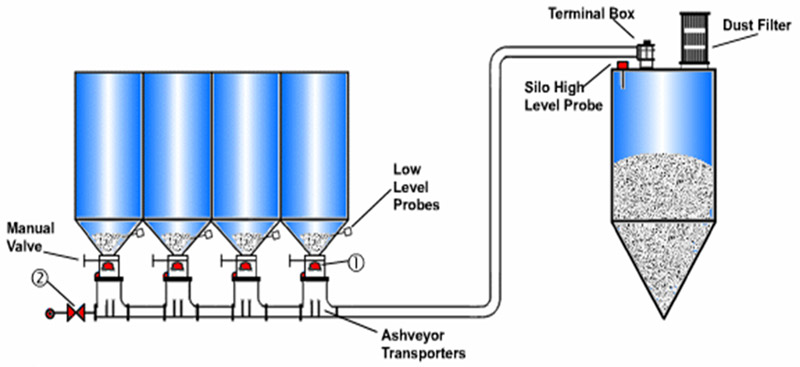

When the boiler is a continuously slagging wet bottom design the ash hopper is replaced with a slag tank. The system consists of installation of Ash Conveying Vessels directly below the fly ash hoppers.

The Better Environmental Option Dry Ash Conversion Technology

Zero water discharge and Boiler Efficiency.

. Plibrico offers the experience and refractory materials needed to make your wet-to-dry bottom ash hopper conversion go smoothly. They are designed so that stored material can be dumped or fed to a process easily. One such technology is a mechanical drag system placed directly beneath the boiler in which bottom ash falls into a water-impounded trough hopper with a chain conveyor at the bottom Figure 1.

To reduce number of conveying pipes from ash. The transition hopper is independently supported from grade floor and could be isolated from the conveying mechanism underneath by optional hydraulically operated bomb bay type doors. Our experience and expertise cover a wide range of industries and applications including power generation renewable power production pulp paper refineries petrochemical and many others.

Bottom Ash Seal Skirt BASS Our Patent pending BASS corrugated seal skirt is unique in the design of the corrugations profile. 4 sieve and 0 to 10 percent passing a 0075 mm No. ProductsServices for Bottom Ash Hoppers.

1316C requiring each system to have a quenching volume of water at the initial collection point bottom ash hopper. The water impounded hopper which receives the ash from the bottom of the boiler is equipped with slide gates that are periodically opened for dumping water and ash in the SCC system. When the boiler is a continuously slagging wet bottom design the ash hopper is replaced with a slag tank.

This design allows for storage of the bottom ash in the hopper in the event that equipment downstream is being serviced or out of operation for any other reason. Bottom Ash Hopper is of structural steel complete with hydraulically operated feed gates refractory lining along with its cooling arrangement hopper overflow water seal boxes sluicing headers with nozzles seal trough overflow connection access doors inspections glass windows poke holes and supporting steel structuring platforms stairs and accessories. We believe the Superbelt design.

Hoppers - 419 companies Hoppers are used for the temporary storage of materials. From quality refractory materials to installation repair and design services our nationwide network of PliPartners is your single. The BASS was designed to combat issues within the bottom ash hopper such as poor expansion contraction mounting waterline corrosion and stress cracking issues at mount point.

For Bottom Ash with water impounded hopper crusher and jet pump is used. These particles then impinge on the furnace walls or fall through open grates to an ash hopper at the bottom of the furnace. This system operates without a quenching volume of water and delivers a.

Numbers of conveying vessels are connected to conveying pipe. This system uses a vacuum design to convey ash in a dry system. Types There are many different types of hoppers dumpers and tippers.

Facility Age Physical Layout and Boiler design type and configuration. Environmental Issues and Benefits. Page 1 of 8 315 S.

Expansion Joint and isolation valve are provided above dome valve. The hoppers are emptied periodically by hydraulic sluicing. FBA may be ground prior to transport and storage.

Typical Surface Impoundment Ash Pond Figure 3. Bottom ash is stored dry in a refractory-lined hopper under the boiler. Our team will work with you to address the challenges you will face during this.

Duke observed low pH events associated with closed loop bottom ash systems and requested design of a caustic pH neutralization system at its Cayuga Station. Bottom ash is predominantly sand-sized usually with 50 to 90 percent passing a 475 mm No. The conveying vessels are equipped with our unique Dome Valve at inlet.

Bottom Ash WTD Conversion Alternatives Presentation Prepared For. Typical Bottom Ash Hopper Arrangement Figure 2. In this system the bottom ash hoppers are filled with water to quench the hot ash which may be as hot as 2400F and are usually lined with refractory.

In this system the bottom ash hoppers are filled with water to quench the hot ash which may be as hot as 2400F and are usually lined with refractory. 1-740-687-4160 or toll-free within North America 1-800-848-5086. The hopper in wet-bottom furnaces contains quenching water.

A more recent development is the completely dry bottom ash conveyor system. National custom designed bottom ash hoppers with vertical lifting doors. Bottom ash hopper maintenance guide.

Conventional Dewatering Recirculation System Bottom Ash may have to be moved and spread to enhance dewatering and achieve proper moisture content to pass EPA Paint Filter Test Any Transport Water may need to be captured collected and returned to the system. Allen-Sherman-Hoff Ash Handling Parts and Service. Molten ash to flow into a hopper below.

No water is needed resulting in reduced cost and time. FBA is composed of the agglomerated particles formed in pulverised coal furnaces that are too large to be carried in the flue gases. The bottom ash feed rate per unit ranges from 1 to 2 tons per hour with an unburned carbon UBC content of around 65.

Clinker grinder reduces crushes bottom ash material to a size sutiable for pneumatic ash conveying. Note offset intake tee for introduction of crushed bottom ash to the pneumatic ash conveying pipeline. The pH adjustment systems included a bulk caustic storage tank chemical feed system control system and.

The hoppers are emptied periodically by hydraulic sluicing. When the molten slag comes in contact with the quenching water the ash fractures. Bottom ash the material that collects at the bottom of the furnace.

The bottom ash hopper are made of heavy steel plate and refractory lined. As by-products of a highly efficient. Bottom Ash Hoppers Vertical Lifting Doors.

Pneumatic Conveying System For Transfer Of Ash And Abrasive Materials

Ash Handling Plant An Overview Sciencedirect Topics

Ash Handling System Components National Conveyors

Jet Pump System Bottom Ash Fly Ash Handling System For Pf Boiler

Coarse Ash An Overview Sciencedirect Topics

Ash Handling System In Thermal Power Plant Ash Handling Plant

0 comments

Post a Comment